DTF printer is direct to film printing printer, using transfer paper with a release liner, using the characteristics of hot melt adhesive powder to adhere to the ink, automatically positioning the hot melt adhesive powder, creating a printing method without cutting and picking.The graphics on the transfer paper can be transferred to the garment through the thermal transfer machine. Even if it is difficult for DTG printer to print on dark fabrics, DTF printer can easily overcome it.

What is the advantage of DTF technology?

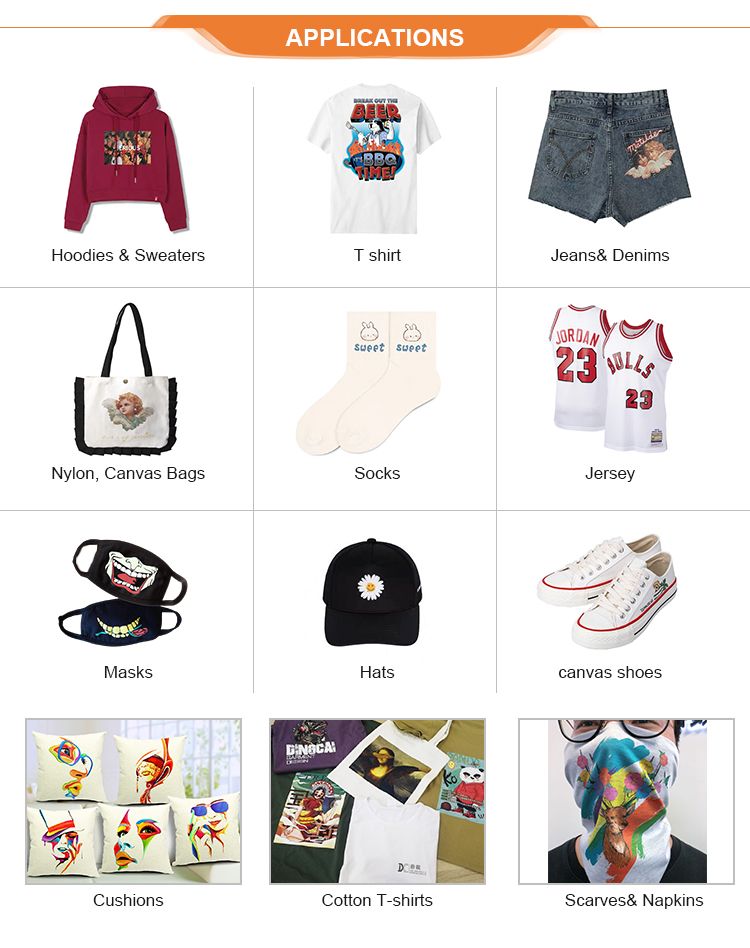

1.Wide range of applications, applicable to a variety of materials.

While DTG prints best on 100% cotton garments, DTF can print on nylon, treated leather, cotton, polyester, 50/50 blends,dark and light colored fabrics.

2.No pretreatment required, speeding up production.

As we all know, DTG printers need pretreatment before printing, and their drying time is longer. But the DTF printer is based on the working principle, the hot-melt powder applied to the DTF transfer can directly bond the printed PET film to the material, which means that there is no need for pre-processing work before printing.At the same time, it can speed up the entire printing process and complete more orders.

3.Save white ink and printing cost.

To print the same pattern and size, DTF printing only needs about 40% white ink, while DTG printing needs about 200% white ink. Saving white ink also saves printing cost, because white ink is used more and the pigment is titanium oxide, so inks of other colors are usually more expensive.

4.Printed patterns are more durable.

Because the ink of DTG printer is applied directly on the clothes, the printed patterns are relatively soft and have almost no hand feeling, but the printed patterns are not as durable as those printed by DTF printers. The DTF printer directly prints on the PET film, which can be washed well and the transferred pattern will not fade or crack or peel off.

5.Flexible use and diverse inventory.

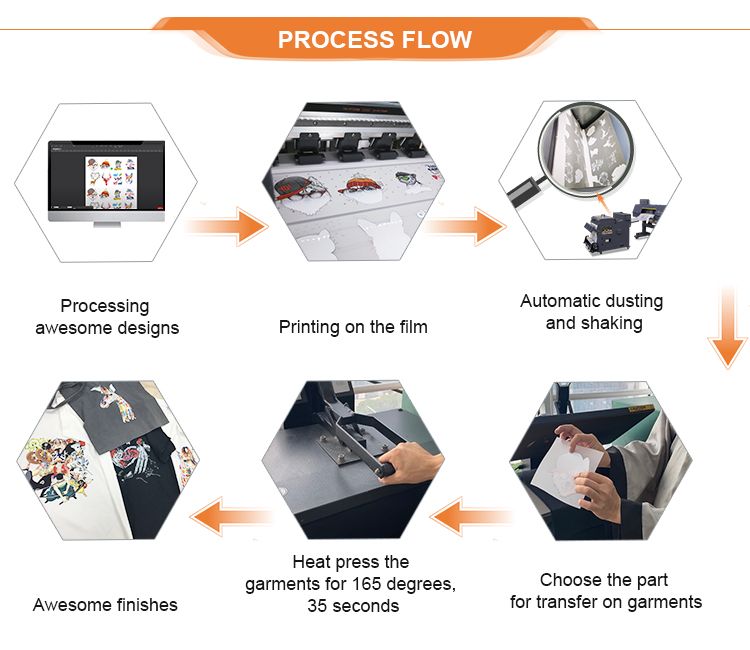

The whole printing process of the DTF printer is to design the printing pattern first, and then print it on the PET film. Second, automatic dusting and shaking. Third, choose the part for transfer on fabrics and heat press fabrics. Finally, you get your DIY fabrics.In the whole working principle, printing onto the PET film to transfer the pattern means that the printed pattern we designed can be transferred to the curved surface or the surface that is difficult to reach. If the product can be heated, then we can apply DTF design to it, because only heat is needed to make the hot melt powder attached to the PET film firmly adhere to the product.

Through DTF printing, popular patterns can be customized and printed in advance, and large-scale printing will not take up too much storage space, and even the printed PET transfer film can be sold directly to customers for custom orders.

To sum up, the current popular DTF printers have 5 major technical advantages:Wide range of applications, applicable to a variety of materials.No pretreatment required, speeding up production.Save white ink and printing cost.Printed patterns are more durable.Flexible use and diverse inventory.

When purchasing a digital printing printer, you must also clarify your printing needs, choose the most suitable printing solution, and create greater benefits.

And our FocusInc has its own production factory and professional technical research and development team, and continues to innovate and produce high-quality UV DTF DTG printers to meet more printing needs of customers. Contact us to start your printing business.

Submit Request